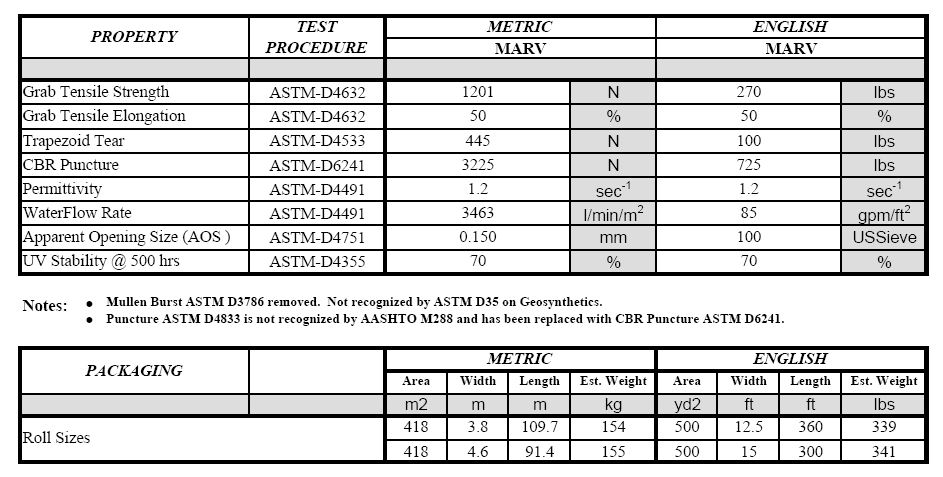

Thrace-LINQ® 125EX

Thrace-LINQ® 125EX is a nonwoven geotextile fabric manufactured from Polypropylene staple fiber. The fibers are randomly oriented and form a cohesive/stabilized needlepunched fabric, for use in many applications. This fabric has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil.

NOTES:

Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.

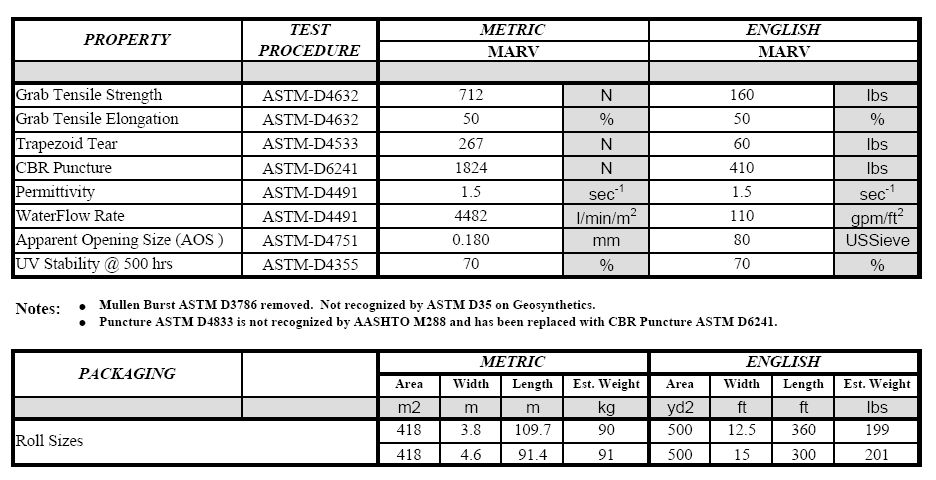

Thrace-LINQ® 130EX

Thrace-LINQ® 130EX is a nonwoven geotextile fabric manufactured from Polypropylene staple fiber. The fibers are randomly oriented and form a cohesive/stabilized needlepunched fabric, for use in many applications. This fabric has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.

LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.

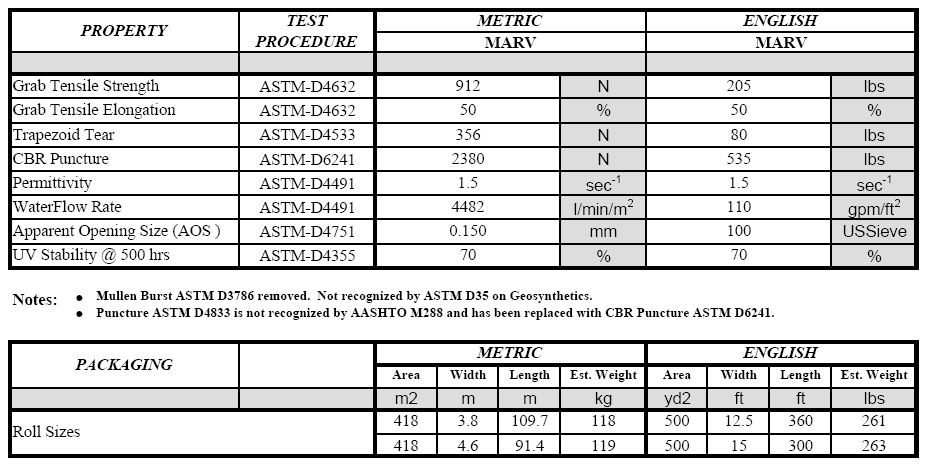

Thrace-LINQ® 150EX

Thrace-LINQ® 150EX is a nonwoven geotextile fabric manufactured from Polypropylene staple fiber. The fibers are randomly oriented and form a cohesive/stabilized needlepunched fabric, for use in many applications. This fabric has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil. Thrace-LINQ® 150EX meets AASHTO M288-06 Class 2 standards.

Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.

LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.

Thrace-LINQ® 180EX

Thrace-LINQ® 180EX is a nonwoven geotextile fabric manufactured from Polypropylene staple fiber. The fibers are randomly oriented and form a cohesive/stabilized needlepunched fabric, for use in many applications. This fabric has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil. Thrace-LINQ® 180EX meets AASHTO M288-06 Class 1 standards.

Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.

LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.

Thrace-LINQ® 250EX

Thrace-LINQ® 250EX is a nonwoven geotextile fabric manufactured from Polypropylene staple fiber. The fibers are randomly oriented and form a cohesive/stabilized needlepunched fabric, for use in many applications. This fabric has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil.

Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.

LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.

Thrace-LINQ® 350EX

Thrace-LINQ® 350EX is a nonwoven geotextile fabric manufactured from Polypropylene staple fiber. The fibers are randomly oriented and form a cohesive/stabilized needlepunched fabric, for use in many applications. This fabric has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil.

Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.

LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.

FRS GTF‐60

FRS GTF-60 is a non woven needle punched polypropylene geotextile meeting the properties listed below.

| Properties | Test Method | English |

| Grab Tensile Strength | ASTM D-4632 | 165 lbs |

| Grab Elongation | ASTM D-4632 | 50% |

| Trapezoid Tear | ASTM D-4533 | 65 lbs |

| Puncture (CBR) | ASTM D-6241 | 400 PSI |

| Permittivity | ASTM D-4491 | 1.5 sec-1 |

| A.O.S. | ASTM D-4751 | 80 U.S. Sieve |

| UV Resistance (500 hrs) | ASTM D-4355 | 70% |

| Mass Per Unit Weight (Typical) | ASTM D-5261 | *6.0 oz/yd2 |

| Water Flow Rate | ASTM D-4491 | 110 gpm/ft2 |

(*Typical Value)

1130 Robertsville Rd., Punxsutawney, PA 15767 Ph: 814‐938‐5000, Fax 814‐938‐0880

FRS GTF-80

FRS GTF 80 is a non woven needle punched polypropylene geotextile meeting the properties listed below.

| Properties | Test Method | English |

| Grab Tensile Strength | ASTM D-4632 | 200 lbs |

| Grab Elongation | ASTM D-4632 | 50% |

| Trapezoid Tear | ASTM D-4533 | 70 lbs |

| Puncture (CBR) | ASTM D-6241 | 500 PSI |

| Permittivity | ASTM D-4491 | 1.4 sec-1 |

| A.O.S. | ASTM D-4751 | 100 U.S. Sieve |

| UV Resistance (500 hrs) | ASTM D-4355 | 70% |

| Mass Per Unit Weight (Typical) | ASTM D-5261 | *8.0 oz/yd2 |

| Water Flow Rate | ASTM D-4491 | 95 gpm/ft2 |

All Values are MARV – Minimum Average Roll Value

(*Typical Value)

FRS GTF-100

FRS GTF-100 is a non woven needle punched polypropylene geotextile meeting the properties listed below.

| Properties | Test Method | Metric | English |

| Grab Tensile Strength | ASTM D-4632 | 1112 N | 250 lbs |

| Trapezoid Tear | ASTM D-4533 | 445 N | 100 lbs |

| Puncture | ASTM D-4833 | 690 N | 155 lbs |

| Puncture (CBR) | ASTM D-3786 | 3115 N | 700 PSI |

| Mullen Burst | ASTM D-3786 | 3171 kPa | 460 PSI |

| Permittivity | ASTM D-4491 | .2 sec-1 | 1.2 sec-1 |

| Permeability | ASTM D-4491 | 0.25 cm/sec | 0.25 cm/sec |

| A.O.S. | ASTM D-4751 | 150mm | 80 U.S. Sieve |

| UV Resistance (500 hrs) | ASTM D-4355 | 70% | 70% |

| Mass Per Unit Weight (Typical) | ASTM D-5261 | 339 g/m2 | *10.0 oz/yd2 |

| Water Flow Rate | ASTM D-4491 | 3463 lpm/m2 | 85 gpm/ft2 |

All Values are MARV – Minimum Average Roll Value

(*Typical Value)

GTF-400EO

Thrace-LINQ® GTF-400EO is woven in a stable weave pattern; using high-tenacity polypropylene monofilament yarns. This geotextile has been UV stabilized and is resistant to commonly encountered chemicals, mildew, and insects, found in soil.

Mullen Burst ASTM D3786 removed. Not recognized by ASTM D35 on Geosynthetics.

Puncture ASTM D4833 is not recognized by AASHTO M288 and has been replaced with CBR Puncture ASTM D6241.

Physical properties reflect industry standards. Roll Data may reflect higher values than those listed above. Roll lengths and widths have a tolerance of +/- 1%.

The property values listed above are effective 09/2012 and are subject to change without notice.

This information relates to the specific material designated and may not be valid for such material used in combination with any other materials or in any process. Such information is, to the best of our knowledge and belief, accurate and reliable as of the date manufactured. However, no representation, warranty or guarantee is made as to its accuracy, reliability or completeness. It is the user’s responsibility to satisfy himself or herself as to the suitability and completeness of such information for his or her own particular use. We do not accept liability for any loss or damage that may occur from the use of this information, nor do we offer any warranty against infringement.

LINQ and the Thrace-LINQ emblem are registered trademarks of Thrace-LINQ, Inc.